Introduction#

Overview of Palletizing Workstation System#

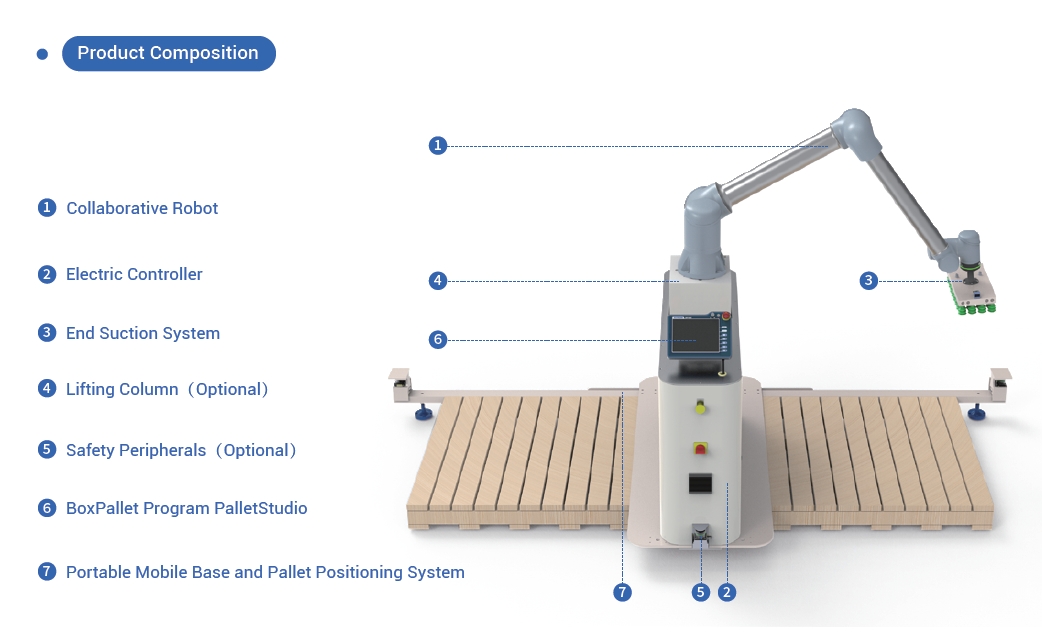

The DUCO PalletStudio palletizing workstation is an integrated hardware and software solution for box stacking applications, consisting of DUCO’s high payload collaborative robots GCR25/GCR16, a palletizing base and a software package for control. Compared to traditional industrial robotic arms, the collaborative robotic arms form a palletizing workstation with a smaller footprint and higher safety, with electronic safety fences supplementing the collision detection of the collaborative robots, without the need for additional fences for protection, and with greater dexterity. This brochure helps customers to understand this palletizing workstation and provides information on how to set up and activate your palletizing configuration.

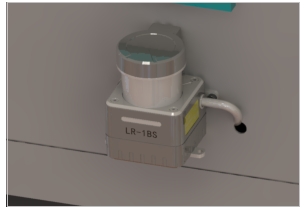

Among them, 1. right line carton detecting quick socket, 2. gas source quick socket, 3. power supply aerial socket, 4. left line carton detecting quick socket. The wiring sequence of the power supply aviation plug is: 1 terminal L → 2 terminals N → 4 terminals PE → 3 terminals are not connected, and the left photoelectric is used by default, and the photoelectric in the accessory box is plugged in with the No. 4 port here.

Introduction to Palletizing Workstations#

The palletizing workstation mainly consists of DUCO-GCR25/GCR16 collaborative robots, electrical control cabinet (including robot controller DC30D-J9), portable mobile base and palletizing plate positioning system, palletizing control system and other parts. The overall palletizing workstation can be fully controlled by our control cabinet.

1 DUCO-GCR25 Collaborative Robot

The collaborative robotics system consists of the following main components:

Robot

Robot control cabinet

Connection cable

Software

Other options, accessories

System Parameters |

|

|---|---|

Degrees of freedom: 6 |

Load (TCP): 25kg |

Workspace: 1800mm |

Repeat positioning accuracy:±0.05mm |

Working Temperature: -10~45 |

IP rating: IP54 |

Installation: Floor-mounted |

|

The parameters of other robot models are shown in the robot product brochure.

2 Pneumatic suction assembly

a Air tubes: These include vacuum air tubes and blowback air tubes, where the outgoing air is used to create negative pressure and the incoming air is used to release the item.

b Suction device (including negative pressure sensors): used to suck up palletized items, the sensor will output a high level signal after reaching a certain negative pressure threshold.

c Robot Tubing Kit: The robot tubing kit is designed to hold the cables for the air tubes and negative pressure sensors along the arm so that they do not get tangled in the arm during suction cup rotation to cause risks such as the air tubes falling out.

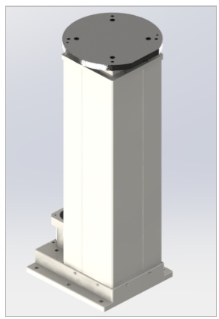

3 Lifting column (or fixed column): controls the raising and lowering of the robot arm, determines the number of layers that can be palletized, and includes the drive and motor.

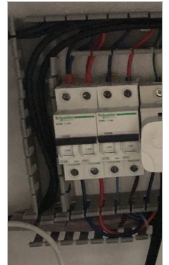

4 Control cabinet components

a DC30D-J9 Controller: The GCR25 is equipped with a controller capable of controlling all the tasks of the overall palletizing station, in the form of a modular workstation in the form of a control cabinet, for rapid deployment and maintenance.

b Circuit breaker: Circuit breakers can be used to protect circuits and equipment from damage caused by overloads, short circuits and other faults, and to ensure the safe operation of circuits. They can also be used to switch circuits and control the start, stop and operation of various electrical equipment.

c On-off switch: Controls the up and down power of the whole station. The white arrow pointing horizontally to the left to O means the circuit is closed, and turning the switch to the right by 90° to point to I will turn on the circuit.

d Safety sensors (optional) for setting up safety zones: used to ensure that the machine stops when there is a person or foreign object in the designated area, and also to monitor that the robot stops when a person enters the robot’s work area.

e Three-color light with buzzer: Provide present status indication, warning to remind the current status.

Palletizing Workstation Specifications#

Model number |

PS-6-STA |

PS-6-FLA / PS-6-PRO |

Working radius |

1800 mm |

|

Maximum pallet size |

1200×1200 |

|

Maximum height |

1600 mm(Fixed base) |

2400 mm(Lifting base) |

Height of lifting column |

not have |

1050 mm |

Maximum lifting height |

not have |

600 mm |

Palletizing speed |

6-8 boxes/min |

|

Repeat Positioning Accuracy |

±0.05 |

|

Communication method |

TCP IP |

|

IP Class |

IP54 |

|

Temperature range |

0~55 ℃ |

|

Rated power |

1.5 kW |

|

Power supply |

100~220 AC |

|

Weight |

370 kg |

430 kg |

Area |

3500×1700(including extension rod) |

|